Concrete Bituminous Concrete Pavement (PCBE) for direct inspection

Concrete Bituminous Concrete Pavement (PCBE) for direct inspection

The differentiated track construction of a Concrete Bituminous Concrete Pavement (PCBE) is part of the Cooperation Term (TC) 497/2012, established between the Transport and Logistics Laboratory (LabTrans), Federal University of Santa Catarina (UFSC) and the National Department of Transport Infrastructure (DNIT), has the objective of evaluating the functions of the Track Control Station (ECP) provided for in the new Automated Integrated Inspection Station (PIAF) model and in the TED Decentralized Execution Term. 448/2017 to examine technological solutions for automated high-speed surveillance.

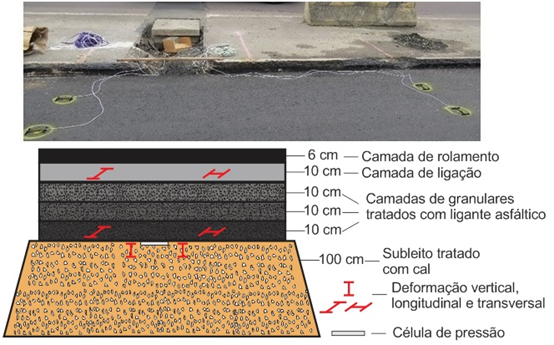

The PCBE is one of the solutions of study of weighing systems in different conceptions of pavement structures, with extension of 120 and 47 cm of thickness of asphaltic concrete, being the reinforced subleito with 1 m of ground layer stabilized with lime, constructed in the BR-101, between km 418 + 440 and km 418 + 560, in the municipality of Araranguá / SC.

The structure and geometry conditions of the PCBE meet the strict criteria defined in the “Class I – Excellent” of the European specification COST 323 (1999), established for Weigh-in-Motion (WIM) systems.

In addition to the construction of the runway, the strain gauge sensors were installed in different layers of the pavement, aiming at studies on the behavior of the pavement structure and, later, on the development of service instructions for standardization in contracting by DNIT.

It is noteworthy that the construction of the PCBE aims at the installation of weighing sensors in motion to control excess weight on Brazilian highways.